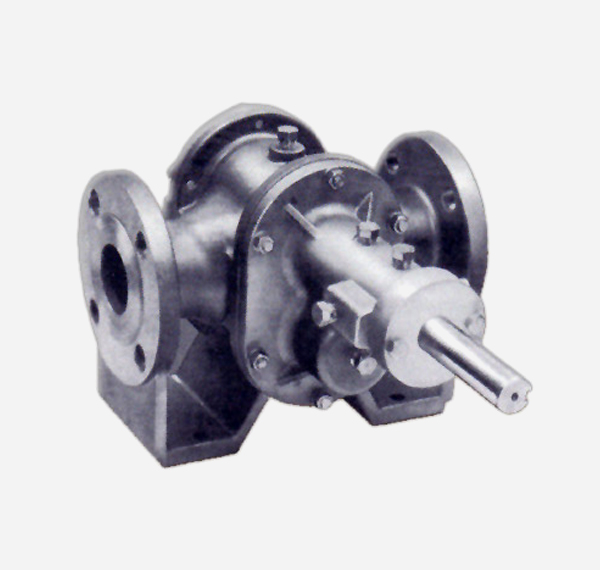

GA16 GEARCHEM PUMP

ECO Gearchem

GA16 Gearchem Pump

Stocked in 316 SS, Alloy C, and Alloy 20.

Consult factory for special sealing requirements. Bearing flush ports, center housing vents port and drain connection are standard.

Because they are expressly designed for chemical service, ECO gear pumps do not include integral/built-in bypass or pressure relief values. Designs with these internal valves can cause heat build-up in the pumped fluid, resulting in accelerated corrosion rates, possible vapor binding or even pump seizure. Instead, ECO recommends the use of externally mounted pressure relief values, piped back to the fluid source.

This pump incorporates all of the engineering experience gained by ECO in over 30 years of designing, building and testing process pumps and the materials that to into them. There is the added feature of parts interchangeability with the Series GA 12 Gearchem pump. Pump components, and a variety of constant or variable speed motors are stocked for quick delivery. Pumps and replacement parts are also stocked in Europe.

This Series GA 16 Gearchem® pump has 2-inch 150 lb. ANSI raised face flanged-ports. This gear pump is designed for transfer and circulation of corrosive, clear, non-abrasive fluids at flow rates in excess of 50 gpm at pressures up to 100 psig.

The GA 16 Gearchem can pump fluids with viscosities ranging from less than 1cP to 100,000 cP and higher. Pump housings are investment cast in a variety of corrosion resistant metallurgies, and components are finish machined on precision CNC equipment.

Metallic and non-metallic gears are machine generated. A variety of materials is available and an existing pump can be quickly converted to satisfy different service conditions. Combination metallic and non-metallic gear sets allow the pump to handle low viscosity and non-lubricating fluids at standard motor speeds. This capability provides reduced noise levels and eliminates the need for larger pumps operating at reduced speeds. Non-sparking gear materials can be supplied for use with hazardous fluids.

Pumps do not require periodic lubrication, since the pumped fluid provides the necessary lubrication and cooling. In addition to reducing maintenance, this feature eliminates the possibility of contamination of the pumped fluid.

Like all Gearchem pumps, the Series GA 16 contains two machine-generated spur gears. Rotating in closely machined center housing and flanked by replaceable wear plated, which protect the faces of the end housings, these gears provide a self-priming pumping action.

In the Gearchem pump, the gears may rotate in either direction, and by reversing drive shaft rotation, the direction of flow can be reversed.

Displacing a constant volume for each specified drive speed, these pumps provide linear, pulsation-free flow. Packages are available for indoor or outdoor location and the pumps are rated for intermittent or continuous service.

Three standard shaft sealing arrangement are: packed lantern ring box, single internal or double mechanical seals.